The History of Parker Hydraulics

In 1975 Richard Parker started a company offering a range of hydraulic hose assemblies, loose hose, couplings and adaptors operating from his home. Soon Richard Parker Hydraulic Equipment Ltd moved into it’s first industrial premises on Ber Street in the centre of Norwich where business continued to grow and within a few years another move into larger premises on Curtis Road in Norwich was necessary. A few years more and again there was need for another move, this time to the nearby Ashbourne Industrial Estate which is still the companies premises today.

The#2 and #3 employees shown here playing chess using Gates hydraulic hose couplings at a trade exhibition in 1985.

David Willimott joined in 1977 (and is still going strong) with Derek Cate following 2 years later, clocking up 27 years before retiring 12 years ago.

Throughout the 80’s and early 90’s the main business was hydraulic components supplied into the agricultural industry, and although this is still key today diversification has meant other market segments such as Oil & Gas, Food & Packaging, Industrial, Construction and Automotive have become a crucial aspect of the Parker business model today.

Exhibition stand at the 1989 Royal Norfolk Agricultural Show.

1995 saw the beginning of a new direction for Parker, with the introduction of pneumatic equipment into the range supported by a partnership with Festo. At this time the company changed its name to Parker Hydraulics & Pneumatics Ltd to reflect these changes. Over the next few years an agreement with IMO Precision Controls added electrical control equipment into the portfolio. As well as the supply of individual control components the company followed a natural progression and today are a complete ‘one stop’ automation solution provider for projects both large and small.

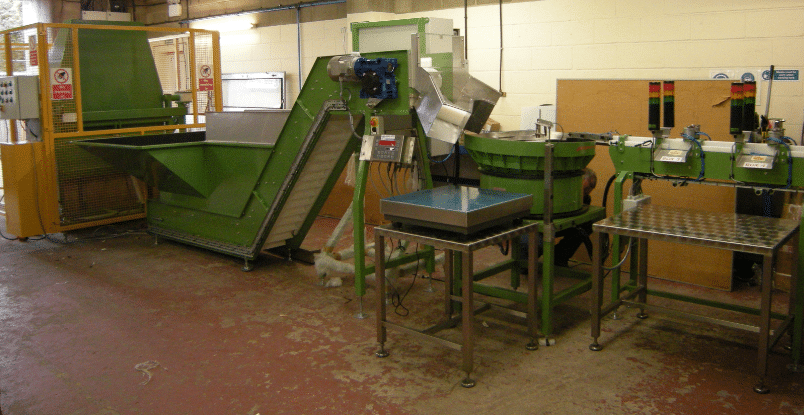

Recent projects have included, amongst others, the hydraulic, pneumatic and electrical control equipment for a complete line to tip, transfer and sort various sizes of glue sticks.

AJF Projects, glue stick tip, transfer and sort system.

The tipper was dealt with by hydraulic cylinder and hydraulic power unit, with a pair of ultrasonic sensors to ensure the tipping is controlled. The transfer from the hopper to the bowl feeder was via an inverter controlled conveyor. The sorting used a number of pneumatic rotary actuators to divert and count the glue sticks into boxes. 3 sizes of glue sticks were chosen on the control panels touchscreen HMI & PLC

Today Parkers have a combined service history of more than 200 years and growing! Why not make contact via telephone, email or through the website to see how they can help you!